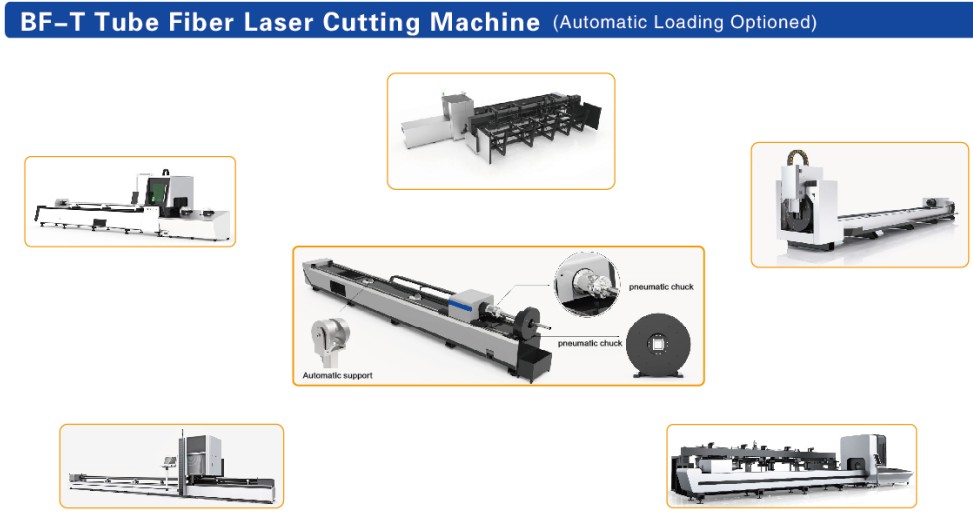

Automatic loading system

Automatic material loading and unloading device is controlled using a numerical control system to feeding the pipes these pipes can be intelligently divided, loaded and connected seamlessly with the pipe cutter to ensure that only one pipe is transported to the delivery arm at a time. This decreases the cost of manually delivery materials

Tube cutting capacity

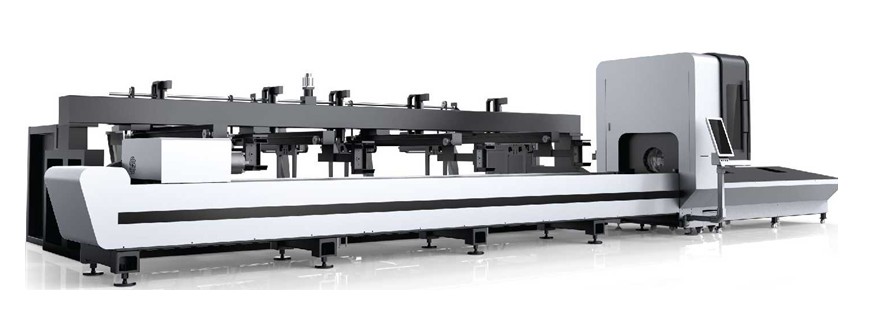

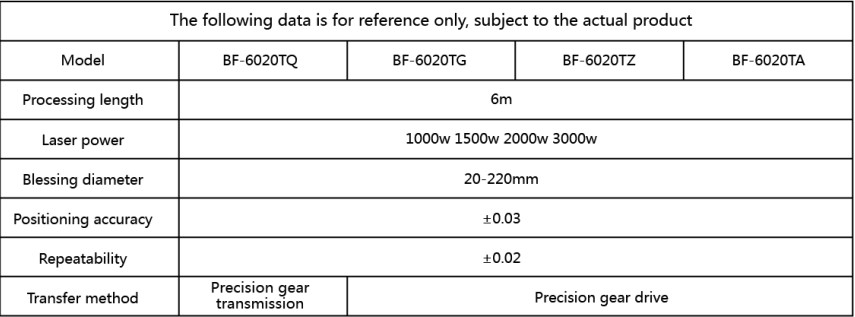

BF-T professional pipe fiber cutting machine.

It can process all kinds of round, square, rectangule, oval tube and horn-type pipe with max. Cutting diameter: round pipe 20-220mm, square pipe 20-160mm;

Running speed is 140m/min, working idle speed is 170r/min, high efficient and time saving.

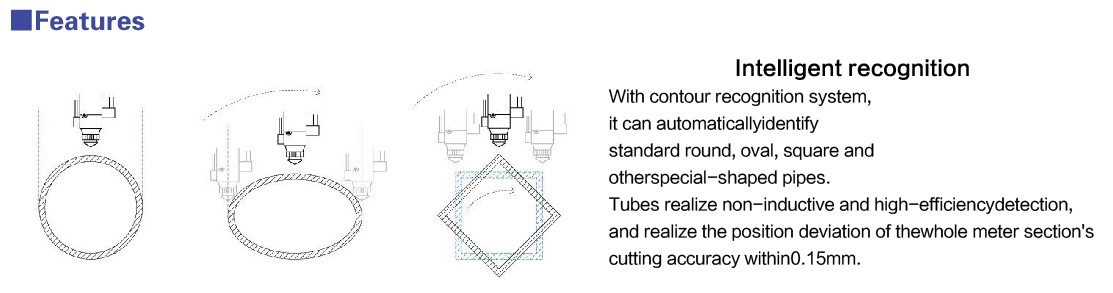

Intelligent recognition

With contour recognition system, it can automatically identify standard round, oval, square and other special-shaped pipes.

Tubes realize non-inductive and high-efficiency detection, and realize the position deviation of the whole meter section’s cutting accuracy within 0.15mm.

Automatic clamping

The front and rear are equipped with fully automatic pneumatic chuck. the diagonal adjustable range is 20-220mm.

Automatic support bracket

Support different types of pipes intelligently,The problem of long pipe deformation is solved

Machine Body

Adopts national standard square tube, 600 ℃ high-temperature heat treatment, 12 meters gantry milling with finishing, 24 hours cooling inside oven ensuring the long-term use of the machine without deform hence the accuracy of the machine is guaranteed.

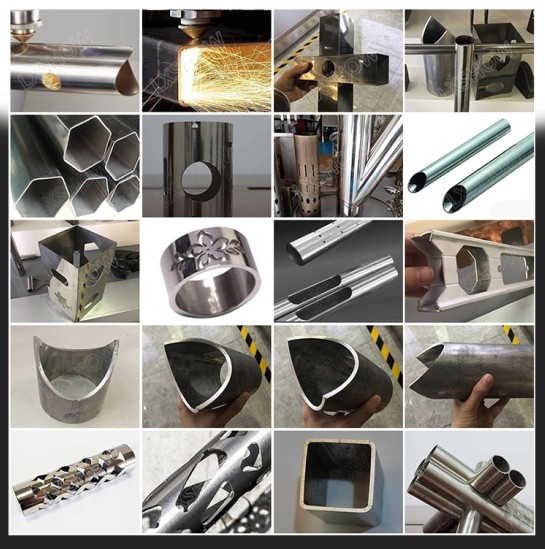

SAMPLES

Tel:+86-531-69956097

Mobile:+86-18615590284

E-mail: tim@biscgroup.com

Skype: Skype

Whatsapp: +86-13906403138